Browsing the World of Fasteners and Machining: Approaches for Precision and Speed

In the detailed realm of fasteners and machining, the mission for precision and speed is a perpetual challenge that demands thorough attention to detail and strategic preparation. From understanding the diverse array of bolt kinds to picking ideal products that can endure strenuous demands, each action in the procedure plays a critical role in accomplishing the desired result.

Understanding Fastener Kind

When selecting fasteners for a project, comprehending the numerous kinds available is critical for ensuring optimum performance and reliability. Fasteners come in a vast array of types, each made for certain applications and demands. Bolts are made use of with nuts to hold materials together, while screws are flexible fasteners that can be used with or without a nut, depending upon the application. Nuts, on the various other hand, are inside threaded bolts that friend with screws or screws, providing a safe hold. Washers are essential for dispersing the tons of the fastener and stopping damages to the product being secured. Furthermore, rivets are permanent bolts that are optimal for applications where disassembly is not needed. Understanding the distinctions in between these fastener kinds is crucial for selecting the right one for the job, making sure that the connection is strong, long lasting, and trustworthy. By picking the ideal fastener kind, you can optimize the performance and long life of your project - Fasteners and Machining.

Selecting the Right Materials

Comprehending the significance of picking the best materials is paramount in guaranteeing the optimum efficiency and integrity of the picked bolt kinds went over formerly. When it involves bolts and machining applications, the product choice plays a critical duty in establishing the general strength, durability, corrosion resistance, and compatibility with the intended atmosphere. Various products supply differing buildings that can dramatically affect the performance of the fasteners.

Usual materials utilized for bolts consist of steel, stainless steel, brass, titanium, and light weight aluminum, each having its special toughness and weak points. Steel is renowned for its high strength and resilience, making it appropriate for a wide range of applications. Selecting the appropriate product entails considering factors such as toughness demands, ecological problems, and budget plan restrictions to make certain the wanted efficiency and long life of the fasteners.

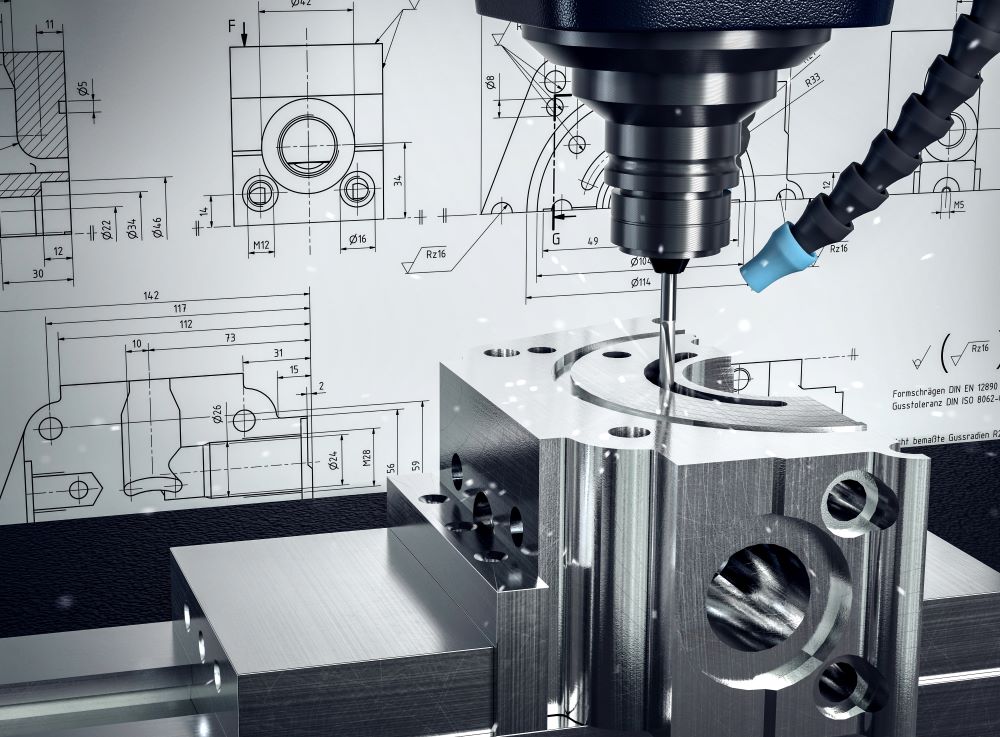

Precision Machining Techniques

In enhancement to CNC machining, various other accuracy strategies like grinding, turning, milling, and drilling play vital roles in bolt manufacturing. Grinding helps accomplish fine surface coatings and limited dimensional tolerances, while transforming is often made use of to produce cylindrical components with precise diameters. Milling and boring procedures are vital for shaping and producing openings in fasteners, guaranteeing they fulfill exact specifications and feature appropriately.

Enhancing Speed and Performance

To optimize bolt manufacturing processes, it is important to streamline procedures and execute reliable approaches that enhance precision machining methods. One key approach for enhancing speed look at here now and effectiveness is the execution of lean manufacturing concepts. By reducing waste and concentrating on continual improvement, lean techniques assist optimize and remove traffic jams workflow. Additionally, spending in automation technologies can significantly increase manufacturing speed. Automated systems can manage repetitive tasks with accuracy and speed, permitting workers to focus on even more complicated and value-added tasks. Embracing Just-In-Time (JIT) supply administration can additionally improve efficiency by making certain that the right products are offered at the correct time, decreasing excess stock and decreasing preparations. Additionally, fostering a society of partnership and interaction among staff member can boost general efficiency by advertising openness, analytic, and development. By incorporating these strategies, manufacturers can attain a balance between rate and accuracy, ultimately boosting their affordable edge in the bolt industry.

Quality Assurance Steps

Carrying out strenuous quality assurance actions is crucial in making sure the dependability and uniformity of fastener products in the production process. Quality assurance actions incorporate numerous phases, starting from the selection of resources to the final evaluation of the finished bolts. One fundamental element of quality assurance is performing extensive material assessments to confirm compliance with requirements. This involves analyzing variables such as product structure, toughness, and durability to guarantee that the bolts meet market requirements. In addition, monitoring the machining refines is vital to promote dimensional precision and surface finish top quality. Utilizing innovative innovation, such as automatic evaluation systems and accuracy measuring devices, can improve the accuracy and efficiency of quality control procedures.

Regular calibration of equipment and equipment is essential to maintain uniformity in manufacturing and ensure that bolts meet the needed tolerances. Carrying out stringent procedures for identifying and addressing issues or non-conformities is essential in protecting against substandard products from entering the marketplace. By establishing an extensive quality assurance structure, makers can promote the online reputation of their brand and provide fasteners that meet the highest possible criteria of efficiency and resilience.

Final Thought

In the elaborate world of bolts and machining, the quest for precision and rate click here for info is a continuous difficulty that demands careful focus to information and calculated preparation. When it comes to fasteners and machining applications, the product choice plays a crucial role in identifying the total strength, durability, corrosion resistance, and compatibility pop over to this web-site with the desired environment. Precision machining entails different advanced methods that make sure the tight tolerances and requirements required for fasteners.In enhancement to CNC machining, other precision strategies like grinding, transforming, milling, and drilling play crucial duties in bolt manufacturing.To optimize bolt production processes, it is vital to simplify procedures and implement efficient approaches that enhance precision machining techniques.